Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

In the rapidly evolving landscape of automation, innovations in robotics are transforming industries and redefining operational efficiency. As we look toward 2025, the concept of "rapid robotics" emerges as a driving force behind these advancements. These technologies are not only enhancing productivity but are also enabling businesses to adapt swiftly to dynamic market demands. From autonomous mobile robots to AI-powered machines, the latest innovations promise to revolutionize the way tasks are performed across various sectors.

In this article, we explore the top five rapid robotics innovations that are set to shape the future of automation. Each breakthrough signals a shift in capabilities and applications, offering unprecedented benefits such as increased precision, flexibility, and cost-effectiveness. As organizations strive to remain competitive, understanding these trends in rapid robotics will be crucial for leveraging their full potential and unlocking new opportunities. Join us as we delve into the cutting-edge developments that are making waves in the automation space and discover how they will influence our working environments and daily lives in the coming years.

The landscape of robotics is undergoing a remarkable transformation, driven by emerging technologies that are fundamentally altering robotic design and functionality. According to a recent report by MarketsandMarkets, the global robotics market is projected to reach $500 billion by 2025, reflecting a compound annual growth rate (CAGR) of 26%. Innovations in artificial intelligence (AI), machine learning, and sensor technology are at the forefront of this evolution, enabling robots to perform increasingly complex tasks with greater efficiency and accuracy.

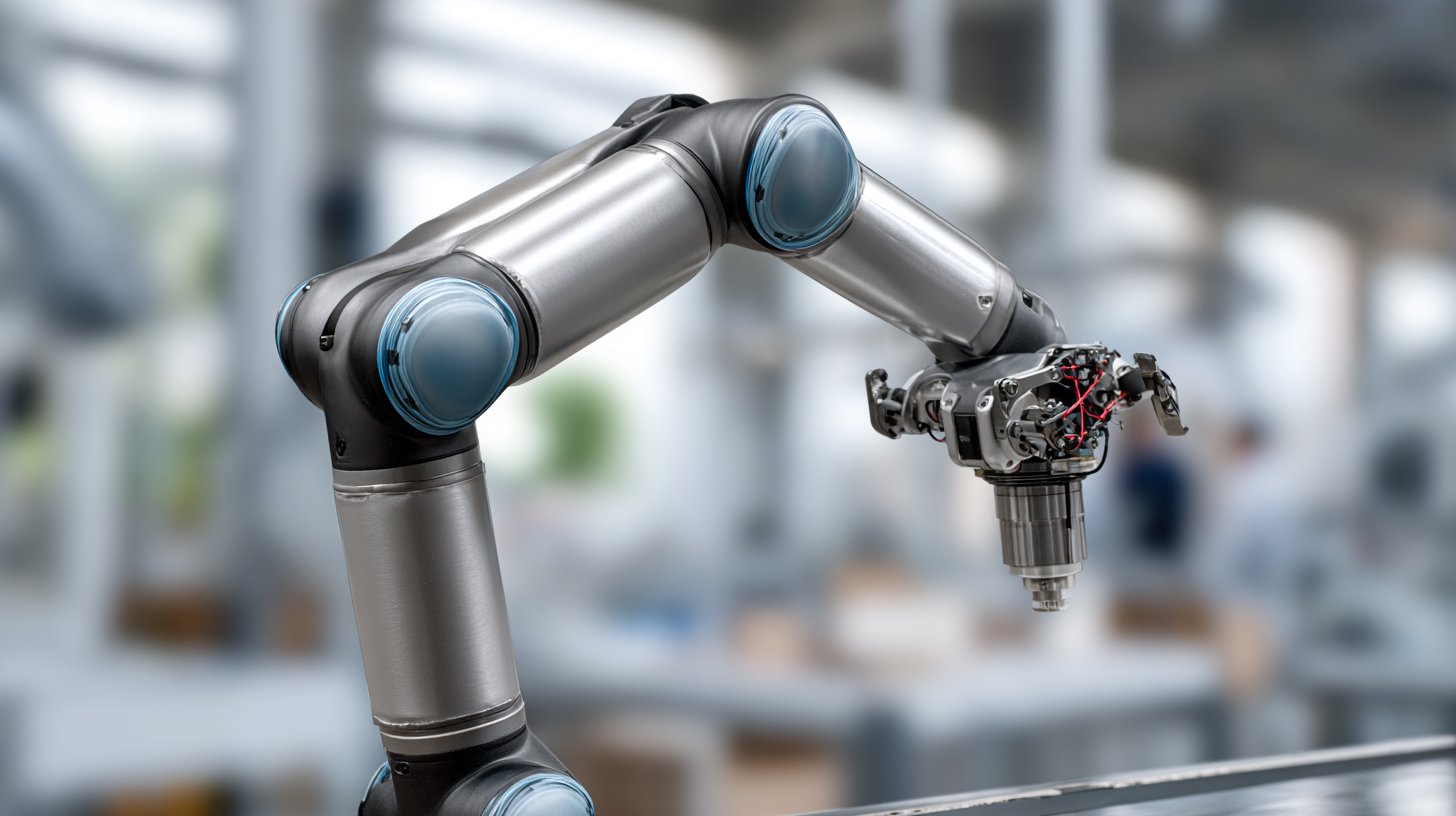

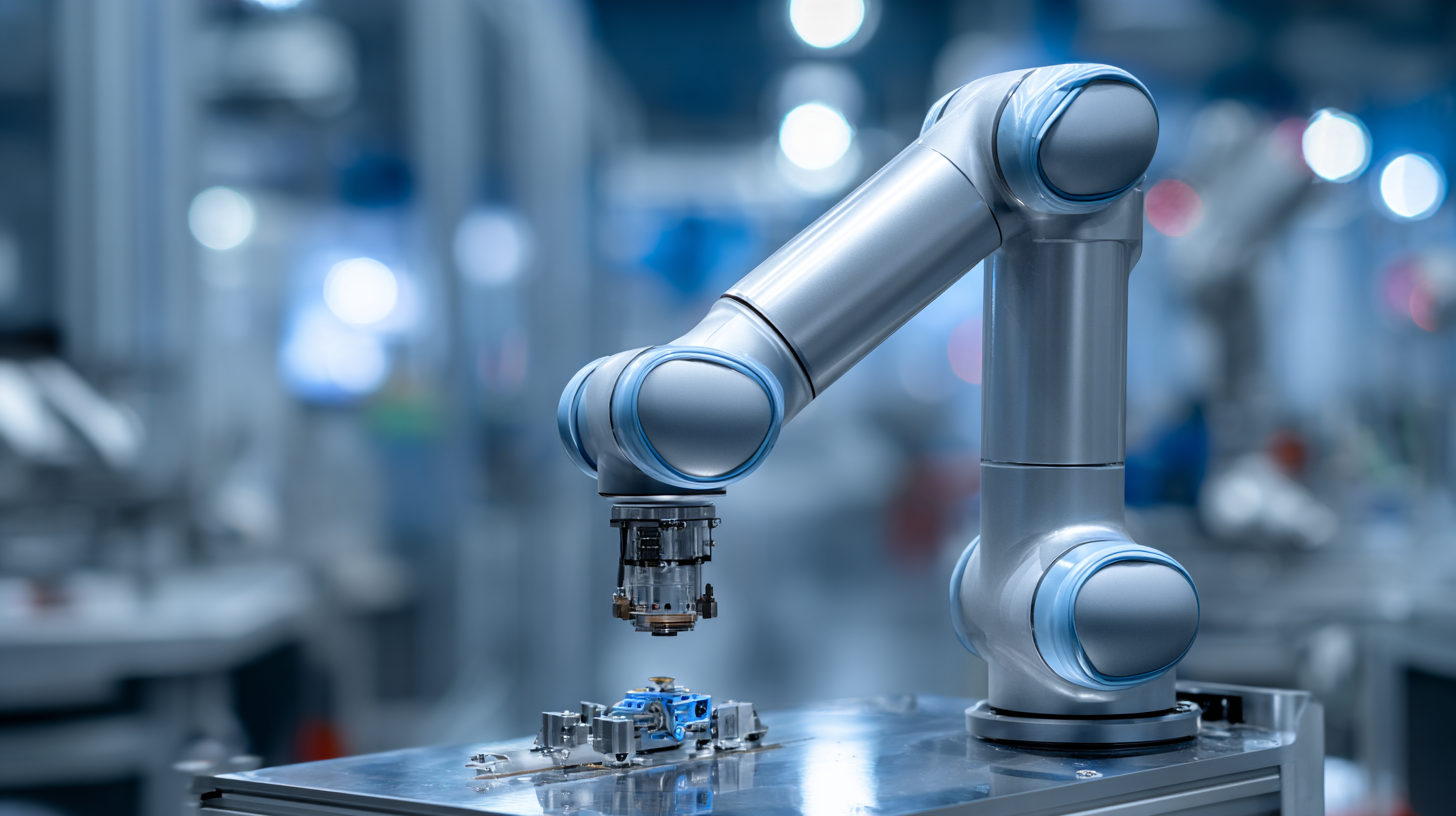

One significant advancement is the integration of collaborative robots, or cobots, which are designed to work alongside humans safely and effectively. A study by the International Federation of Robotics highlights that the use of cobots is expected to surge by 40% annually over the next five years, as businesses recognize their potential to enhance productivity without replacing human workers. Furthermore, advancements in materials science have led to the development of lightweight, flexible robotic structures, making it easier to deploy robots in space-constrained environments. This fusion of cutting-edge technologies is not only revolutionizing the capabilities of robots but also redefining the roles they play across various industries, from manufacturing to healthcare.

The rapid advancement of AI-driven automation is revolutionizing the landscape of robotics, significantly enhancing decision-making processes across various industries. By integrating sophisticated algorithms, robotics can now analyze vast amounts of data in real-time, enabling machines to make informed decisions quicker than ever before. This capability not only streamlines operations but also minimizes human error, allowing for a more effective and efficient workflow.

Moreover, AI-powered robots can adapt to dynamic environments and changing task requirements. Their ability to learn from past experiences means they can refine their strategies over time, further improving productivity. For instance, in manufacturing, robots equipped with AI can optimize production schedules based on real-time inventory and demand levels, ultimately leading to reduced costs and increased output. The convergence of AI and robotics sets the stage for a future where machines are not just tools, but intelligent partners in driving innovation and efficiency across sectors.

As automation continues to evolve, collaborative robots, or cobots, are at the forefront of transforming how humans interact with machines. Unlike traditional robots that operate independently, cobots are designed to work alongside human workers, enhancing productivity and safety in various environments. They can take on repetitive or dangerous tasks, allowing humans to focus on activities that require creativity and critical thinking. This synergy not only increases efficiency but also fosters a more inclusive workplace where human skills are valued and enhanced.

Tip: When integrating cobots into your operations, start small. Identify specific tasks where collaboration is beneficial and pilot the technology in a controlled environment. This approach allows for thorough evaluation and adjustment, ensuring a smoother transition.

Moreover, the adaptability of cobots makes them an attractive option for businesses of all sizes. They can be easily programmed and reprogrammed for different tasks, making them versatile tools in dynamic industries. This flexibility empowers companies to scale operations rapidly while maintaining a high level of quality and precision in production.

Tip: Invest in training your workforce on how to work effectively with cobots. By understanding the capabilities and limitations of these machines, employees can collaborate more effectively, leading to a safer and more productive work environment.

| Innovation | Description | Key Benefits | Application Areas |

|---|---|---|---|

| Collaborative Robots (Cobots) | Robots designed to work alongside humans in a shared workspace. | Increased productivity, enhanced safety, and flexibility in operations. | Manufacturing, warehousing, and assembly lines. |

| Autonomous Mobile Robots (AMRs) | Self-navigating robots for material transport within facilities. | Improved efficiency, reduced labor costs, and enhanced logistics. | Warehousing and distribution centers. |

| AI-Powered Robots | Robots equipped with artificial intelligence for decision-making. | Improved adaptability, advanced problem solving, and predictive maintenance. | Healthcare, agriculture, and manufacturing. |

| Soft Robotics | Robots made of compliant materials for safer human interaction. | Increased safety, versatility, and handling of delicate objects. | Food processing, packaging, and medical applications. |

| Exoskeletons | Wearable robots that augment human strength and stamina. | Reduced fatigue, increased lifting capabilities, and improved ergonomics. | Construction, healthcare, and manufacturing. |

Cloud robotics is revolutionizing the landscape of automation by providing scalable and flexible solutions that cater to a diverse range of industries. By leveraging cloud computing, businesses can access vast resources and intelligent algorithms without the burden of heavy infrastructure investment. This shift allows companies to quickly adapt to changing demands, optimize operations, and enhance productivity. Moreover, the ease of collaboration facilitated by cloud robotics means that teams can work seamlessly across geographical boundaries, fostering innovation and efficiency.

Tips: When integrating cloud robotics into your operations, start with clear objectives. Assess your current processes to identify automation opportunities and prioritize them based on potential impact and feasibility. Additionally, ensure robust cybersecurity measures are in place to protect sensitive data and maintain trust in your automated systems.

Furthermore, cloud robotics enables continuous learning and improvement. Machines can update their knowledge base in real-time, responding to new data and enhancing their performance. This capability not only leads to smarter automation but also reduces downtime by anticipating issues before they escalate. By embracing these innovations, businesses position themselves at the forefront of the automation revolution, ready to meet future challenges head-on.

Tips: Keep an eye on emerging technologies within cloud robotics, such as artificial intelligence and machine learning, as they can further enhance automation capabilities. Stay informed on best practices to maximize the efficiency of your robotic systems and leverage cloud solutions to their full potential.

The rapid advancements in robotics present groundbreaking opportunities across various industries, yet they also raise complex ethical considerations. As robots become increasingly autonomous, questions about accountability arise. For instance, if a robotic system makes a mistake leading to harm, who is held responsible? The developers, the users, or the machines themselves? Establishing clear guidelines and regulations is crucial to navigate this landscape and ensure that responsibilities are well defined.

Moreover, the integration of robotics into the workforce prompts concerns about job displacement and economic inequality. While automation can enhance efficiency and productivity, it may also lead to significant job losses in certain sectors. It becomes essential to consider how to retrain and support workers whose roles are being replaced by robots. Additionally, ethical frameworks must be developed to guide the design and implementation of robotic technologies, ensuring they promote social good without compromising human dignity and rights. Addressing these ethical issues is vital as we embrace the future of automated solutions.

The chart above illustrates the adoption rates of various rapid robotics innovations that are transforming automation. With AI integration leading the charge at 75%, followed closely by machine learning, these technologies are reshaping industries and driving future advancements.

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift